EMS

Factory Photos

Production line scale

(1)24 ASM SMT lines

(2)8 Panasonic AI DIP machines

(3)4 lead free wave soldering lines, able to increase to 8 lines

(4)8 assembly lines, able to increase to 16 lines; 4 packaging lines, able to increase to 8 lines

(5)Actual max mounting points 3 million per hour; 1.7 billion points per month

(6)All machines compatible to MES

(7)SPI/AOI equipped each line

(8)Each line equipped with NG-Buffer after SPI/AOI to enable non-stop automatic production, optimizing producing capacity

(9)Several SMT configuration with combination: 1+1, 2+2, 3+3, double track to meet variety of custom needs, controlling cost

(10)13-zone reflow oven, compatible to fill with Nitrogen

|   |   |

|   |   |

|   |   |

|   |   |

|   |   |

Typical 3+1 SMT configuration

Major Equipment

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Intelligent Distribution& Store System

JIT has introduced a set of sophisticated digital systems, including ERP, MES, WMS, OEE etc., providing a platform to integrate corporate activities organically in order to optimize effectiveness, reduce cost, control warehouse storage, decrease numbers of human labor and keep mistakes in minimum range. This enables JIT rapidly responds to market change, keeps capacity at a positive level against risk and results in corporate high competitiveness.

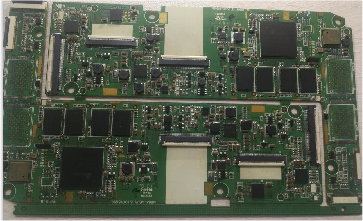

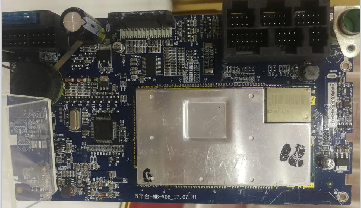

PCBA Cases

Industry Control

|   |   |

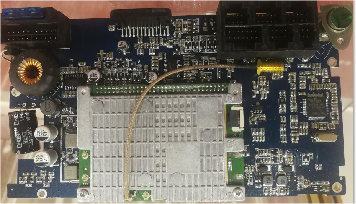

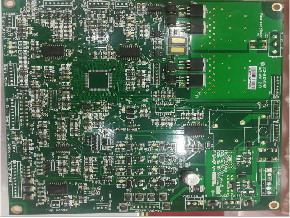

Communication

|

|

|

|

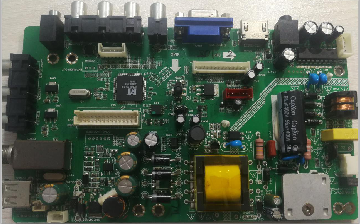

Consuming & Automotive Electronics

|

|

|

|

|

|

End Products

|   |   |

|   |   |

|   |   |

|

Link:Earth Network

Copyright © 2020-2022 赣ICP备19014000号-1 Jiangxi Intelligent Electronics Technology Co., Ltd.

Copyright © 2020-2022 赣ICP备19014000号-1 Jiangxi Intelligent Electronics Technology Co., Ltd.